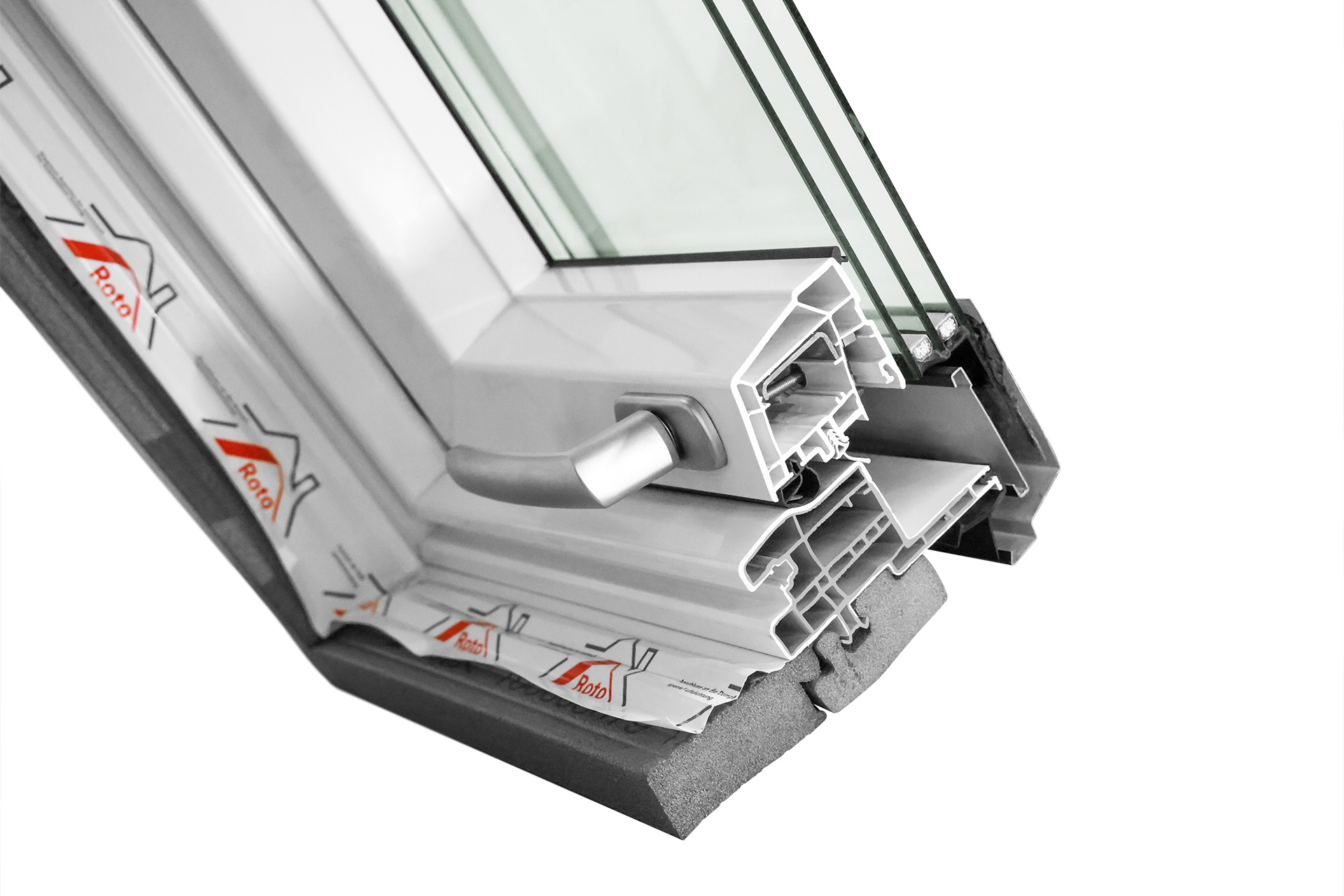

Roto roof window made of 100% PVC hollow chamber profile.

The Roto original since 1995

Roto has been perfecting durable roof window solutions made of fiber-reinforced PVC for 30 years. The 100% PVC hollow chamber profiles ensure maximum stability and energy efficiency - ideal for professional use and demanding renovation projects that focus on lasting customer satisfaction and sustainability.

Whether it's the RotoQ or the Designo family, whether pivot, or top-third pivot or top-hung windows, operated by hand or by smartphone: all Roto roof windows that are offered as PVC variants are made of pure PVC and steel.

The advantages of Roto PVC windows

Maximum durability and stability

The high-quality PVC hollow chamber profiles combined with steel reinforcements are extremely resistant to external influences and retain their shape over the long term.

Outstanding energy efficiency

The modern hollow chamber technology

optimizes insulation and reduces heat loss, which contributes to more efficient energy use in the building.

Almost 100% recyclable

The main 1 components of Roto PVC windows can be fully recycled back into the raw material cycle thanks to their pure composition. This is how windows can become windows again!

1 The main components are glass, metals and PVC.

Comparison: PVC hollow chamber profile vs. Wood-PVC profile

|

PVC Hollow- |

Wood-PVC |

Explanation |

|

|

Selection of raw materials |

The use of recycled PVC in the hollow-chamber profile has been shown to have a significant positive effect on the CO2 balance, without compromising on product quality. The visible surfaces shine in pure white and meet the highest aesthetic standards, as the recycled material is used exclusively inside the PVC profiles and thus remains invisible. While the wood-PVC profile is notable for its use of a renewable raw material, it is less environmentally sustainable due to its limited recyclability. |

||

|

Recyclability |

Our PVC hollow chamber profiles are designed to be easily recycled. The profiles are reinforced with steel to provide the necessary structural stability. At the end of their life cycle, the frames can be easily disassembled into their components – PVC and steel - and recycled separately. This recycled PVC is then used to create new products and is incorporated into the non-visible areas of our PVC profiles, further contributing to sustainability. In contrast, composite materials such as wood-PVC frames are generally not recyclable because separating the components is technically difficult or not economically viable. As a result, they often end up in waste incinerators, whereas PVC hollow chamber profiles actively contribute to the circular economy. |

||

|

Durability |

PVC is extremely resistant to external influences and requires very little maintenance. Even when screws are used for interior fittings, such as roller blinds or shutters, the hollow chamber profile remains unaffected. In contrast, with wood-PVC combinations, the protective PVC layer can be damaged by screw holes, allowing (air) moisture to penetrate the wooden core. Since the wood is completely enclosed, it cannot dry out, which in the worst case can lead to rot. PVC profiles avoid this risk and impress with their durability and low maintenance requirements. |

Wood-PVC combination can have disadvantages

Wood itself has many desirable qualities that make it an excellent choice for windows. It provides great insulation, offers high stability, and has a very elegant look. However, if a timber window is encased in PVC and screwed to the exterior roof structure and water enters the timber core through the screws, the material can begin to deteriorate. If the plastic sheathing protecting the window core is damaged, moisture from rain, condensation, or water vapour can easily seep into the core. This often happens during installation when screws are driven into the frame. The potential consequences include mold growth, rotting wood, reduced structural stability, and even the complete damage of the window. In such cases, a costly and entirely avoidable roof window replacement becomes necessary. Roto windows are designed to eliminate this risk. All Roto roof windows are engineered without screws in the water-exposed outer shell, preventing moisture penetration from the outside. With Roto roof windows, such damaging scenarios are effectively avoided.

By the way: Roto roof windows are delivered completely pre-assembled. This means that there is no need to screw anything into the frame during installation. All the roofer has to do is align the window to the roof battens and screw it in place. Damage to the roof window surfaces is a thing of the past - and the longevity of your Roto roof windows is guaranteed!

/roto-logo%20EN.jpg?width=256&height=113&name=roto-logo%20EN.jpg)

/Stairs/Roto_Marke_Treppe-DE-color.png)

/Stairs/NL-roto-logo-de-trappen-color.png)

/Stairs/PL-roto-logo-schody-color.png)

/Stairs/IT-roto-logo-la-scala-retrattile-color.png)